Design

— idea generation —

— Representation —

— determining contraints —

We will work with you in the planning phase, problem solving, reviewing and refining for final verification of manufacturability, in addition to presenting you with sketches and renderings to demonstrate concepts, details and final designs.

Modelling

— 2D 3D creation —

— Rendering development —

— existing 3d Modification —

With our in-house Unigraphics CAD system or utilizing the expertise of one of our strategic partners we can help you complete your design with virtually any other CAD system.

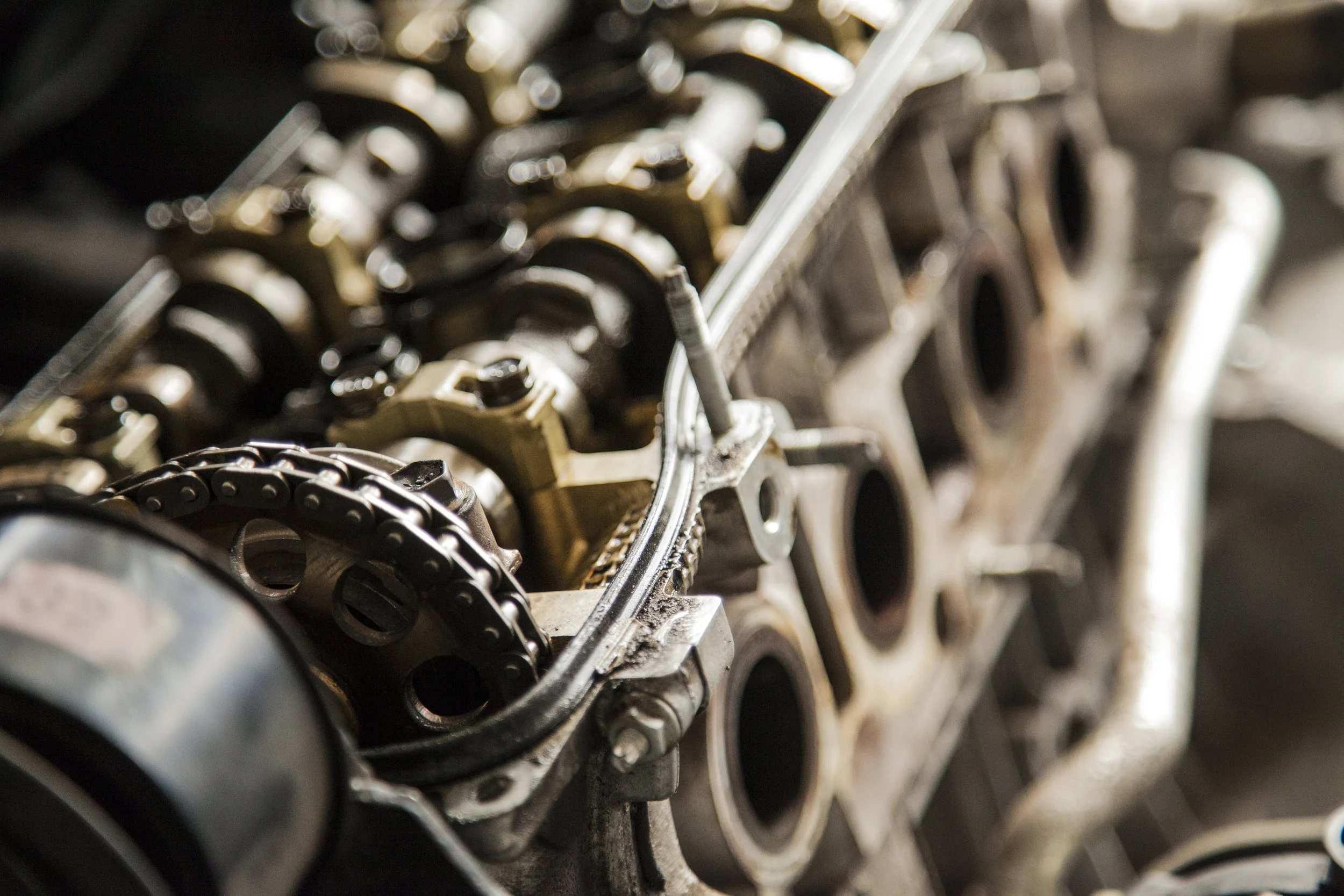

Fully designed via our in house associative Unigraphics CAD/CAM system Prototype parts, patterns and core boxes can be quickly CNC machined using aluminum, cast iron and a wide variety of tooling boards including ureol type resins.

— RAPID PROTOTYPING —

— CNC MACHINING —

— RAPID TOOLING —

— POLYURETHANE AND EPOXY CASTINGS —

— SIMULATED DIE CASTINGS FROM PLASTER —

Vacuum & Thermoforming

Patterns & Prototypes has the expertise to fabricate contoured moulds from a variety of materials, for the vacuum forming and thermoforming of plastics.

Whether your needs are prototyping product shapes for fit and verification using low cost composites or creating aluminum production tooling, our skilled patternmakers working with the latest CAD/CAM software and CNC machinery will efficiently service all your vacuum forming needs.

Punchdie & Wire EMD Services

Whether reproducing an existing part for obsolete equipment, creating copies of old tooling, or redesigning a foreign patented product to get a new look, Patterns & Prototypes can help. We will assist you to visualize your part in a 3d perspective, make alterations, rework surfaces and when you are satisfied our toolmakers will create tooling from the “virtual prototype” reducing the need for old fashion drawings or even a prototype.